Automated Image Processing for D2C

We built a deterministic computer vision system that standardizes SKU prep and scales catalog production predictably.Client

A growing D2C brand from Eastern Europe selling custom paint-by-numbers kits. Every new design required manual preparation before production, similar to any highly customized visual product line.

The client was gaining early market interest, but growth stalled once it became clear that the fully manual workflow, including color cleanup and outline preparation, could not support a larger catalog.

To expand, the business needed a way to prepare visual assets faster and more consistently. This is when the client came to us to explore whether the process could be automated without compromising quality.

Challenges

Before any design could be turned into a physical kit, it went through several stages of manual preparation: color-zone evaluation, outline cleanup and visual adjustments. Even small lighting or contrast differences changed how the final canvas looked, so designers had to manually adjust every new image.

Preparing each new SKU routinely took 8–10 hours, and the workload grew linearly with the catalog. Each additional design increased production cost and slowed release cycles, eventually creating a capacity ceiling that prevented the client from releasing new SKUs at the pace the business needed.

In 2022, commercially reliable generative models did not exist, so the only workable solution was to build a deterministic computer-vision pipeline that could scale with the business.

Handling high-resolution images reliably

Paint-by-numbers kits require high-resolution source images with precise color regions. Processing such files at scale created challenges around memory usage, processing time and preservation of fine contour details. Our solution had to handle heavy images consistently and without performance issues, otherwise the bottleneck would simply shift from people to infrastructure.

Building a deterministic raster-to-vector pipeline

Source images varied widely in lighting, contrast and artistic style. We needed a pipeline capable of turning any input image into a stable vector layout with clean shapes, accurate segmentation and a palette suitable for physical production.

This required predictable, rule-based behavior rather than any form of generative processing.

How we solved it

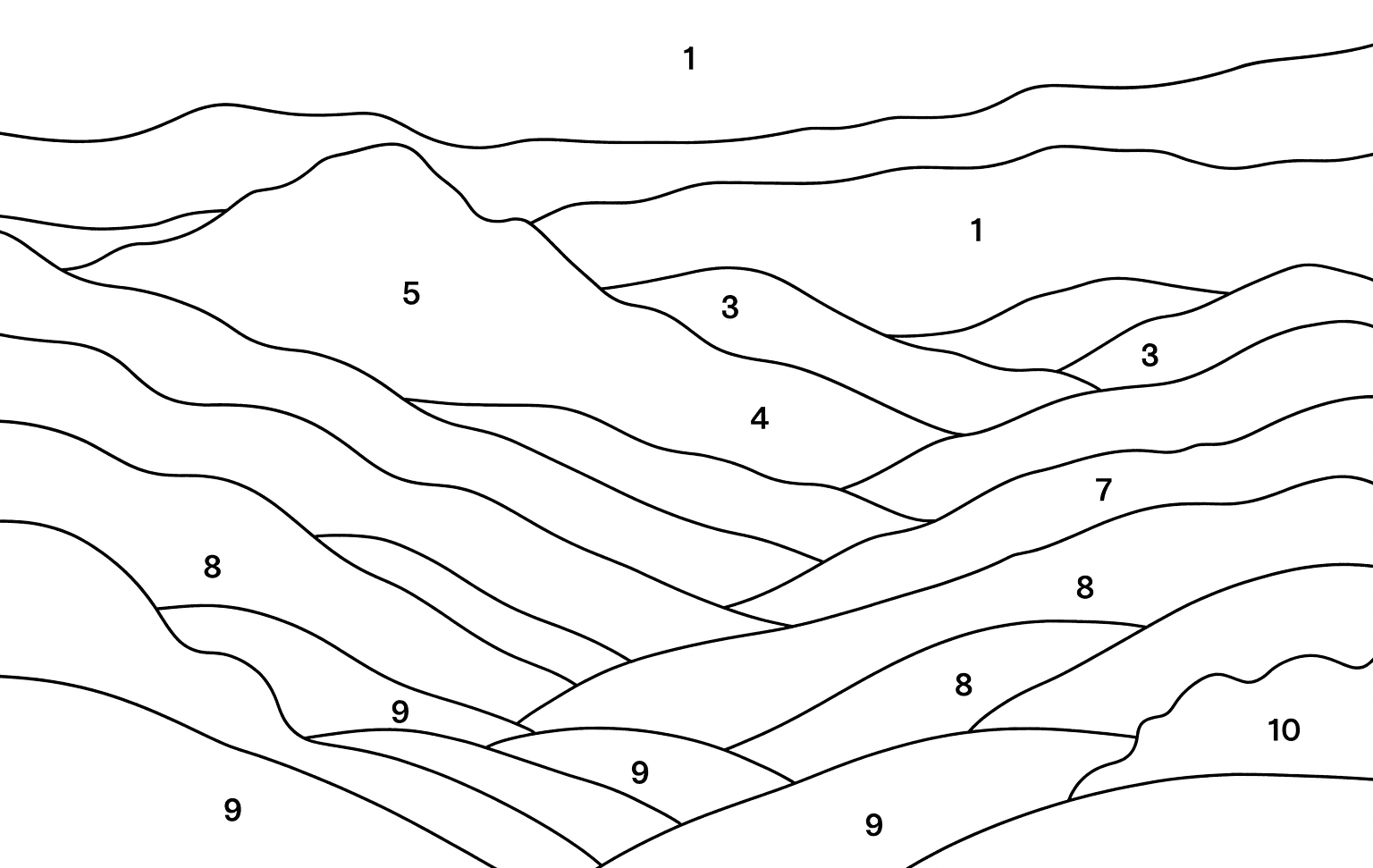

1. Automated segmentation and outline generation

Custom computer-vision algorithms detect structural elements in the input image and convert them into clean, reproducible vector contours. The process produces consistent outlines across different inputs, which is essential for maintaining consistent production quality as the catalog grows.

2. Noise reduction and line optimization

The pipeline removes visual noise and smooths irregular boundaries while preserving essential geometry. This eliminates the manual cleanup stage that previously consumed most of the designer’s time.

3. Color-palette extraction and mapping

The system analyzes each image, groups similar tones and converts them into a consistent set of colors suitable for production. This removes the need for designers to define or fine-tune shades by hand for every new design.

4. Final layout generation

Each processed image is transformed into a structured, production-ready template: clean vector outlines, numbering of paintable regions and the final palette reference. This gives the client predictable, repeatable output suitable for manufacturing.

5. Performance optimization

The pipeline was optimized to handle large, high-resolution images without performance degradation. Memory-efficient processing steps keep speed and stability consistent even as design volume grows.

Result

We built an automated image-processing pipeline that transforms any uploaded image into a ready-to-produce paint-by-numbers layout. A process that once relied on hours of manual labor became fast, predictable and able to support ongoing catalog expansion.

What previously required 8–10 hours of designer work now takes around 2–3 hours end to end. The client gained the operational capacity to release new SKUs at the pace the business needed, keep the catalog fresh and scale output without adding staff.

With a stable production pipeline in place, the business became more resilient. Release cycles stopped depending on individual designers, timelines became predictable and the client could confidently broaden the product line, including a digital coloring-game experience based on the same core technology.

SKU launch cycles without adding headcount.

instead of 8–10 thanks to automated image processing.

What happens next:

Having received and processed your request, we will reach you shortly to detail your project needs.

After examining requirements, our analysts and developers devise a project proposal with the scope of works, team size, time and cost estimates.

We arrange a meeting with you to discuss the offer and come to an agreement.

We sign a contract and start working on your project as quickly as possible.